Description

☆Package

BMS{Bluetooth bulit-in}

* Temperature sensor(40cm)

* Balance Wires(75cm)

* Active Switch(15cm)

*Heating cable(Only for BMS With Heat Function)

H:BMS With Heat Function

C:BMS With CANBUS chip Bulit-in

NOTE: For instructions on heating cables,

the green 5PIN cable of the heating cable needs to be linked to the heating pad,

and the rest of the black and red cables are linked to the smart charger

(after the smart charger links the BMS,

it detects the temperature of the battery through the BMS,

which automatically monitors the charging status of the battery)

Heat Function interface

Description of heating function:

Battery temperature is below low temperature charge protection, turn off charging, turn on heating.

Cryogenic charge protection is a parameter that can be set within APP

The heating power depends on the battery voltage and the resistance value of the heating film.

Battery voltage U.

Heating resistance R.

Power equals U*U/R

Heating current I=U/R;

The maximum I (current) of the board design is 3A.

MAX heating power 200W(100W OF B2A8S20P).

☆ Pls buy the accessory from the following link.

//www.aliexpress.com/item/3256803264785657.html

☆ Bluetooth link for Phone-JIKONG BMS

Download link-IOS : Search (JIKONG BMS) in the APP STORE

Download link-Andriod : Search (JK BMS) in the Google STORE

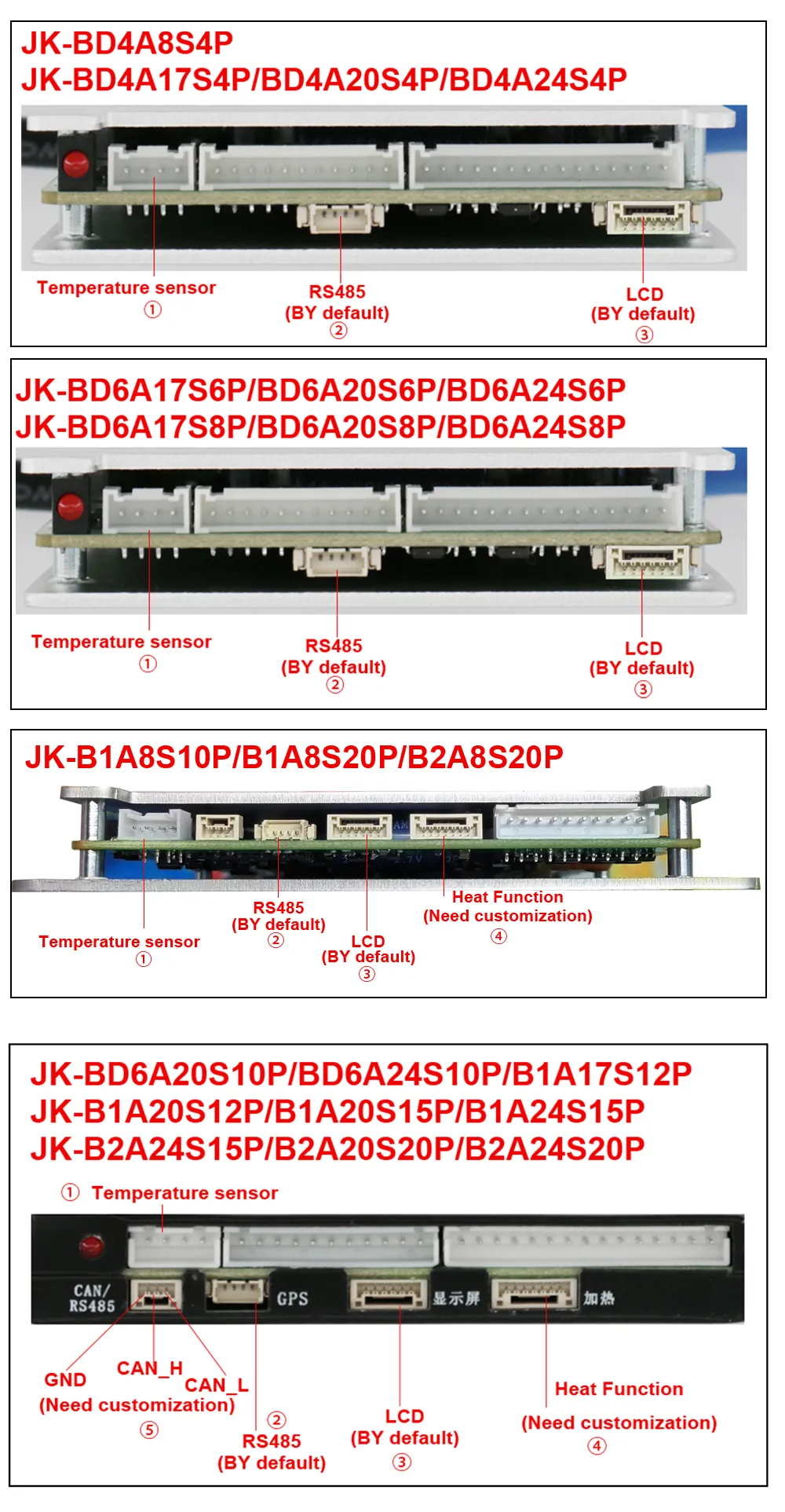

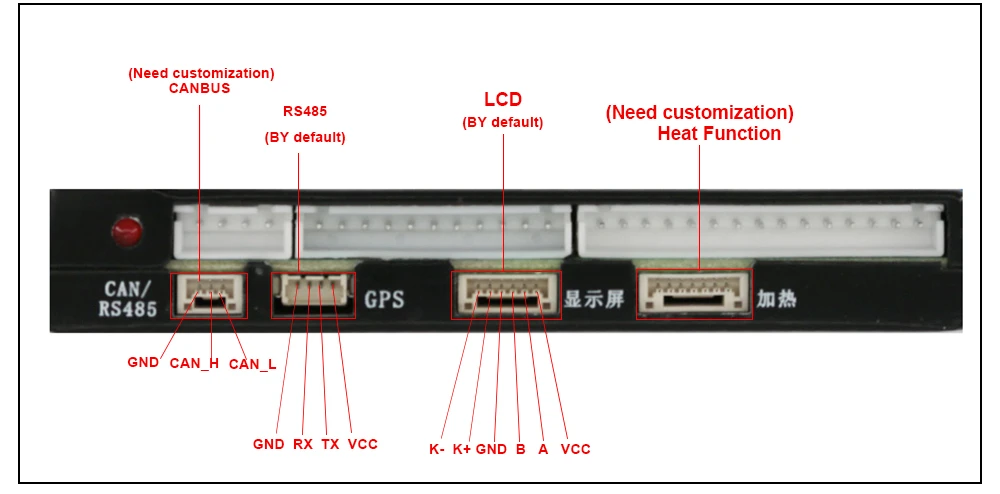

NOTE:

①:Temperature sensor

②:RS485 interface(At present, all JK BMS are configured with RS485 function by default)

③:LCD interface(At present, all JK BMS are configured with LCD interface by default)

④:Heat Function interface(At present, the heating function customized by customers can be accepted)

⑤:CANBUS interface ( Needs customized)

NOTICE:

Protection (Current Sensor Anomaly)

This problem exists when the inverter is used, because the current direction is uncertain,

The alarm will be displayed. It does not affect the normal use of BMS.

This kind of alarm will appear when the sun is not big or small, because at this time,

the battery fluctuates frequently between charging and discharging,

and there are uncertain factors, so this problem occurs.

A pure sine wave inverter does not draw a constant current. The current from the battery follows a sine wave shape.

It ramps from zero current up to peak current in 1/4 of a cycle.

The peak current is actually about 40% more than the average current.

Then the current will ramp back down to zero at the 1/2 cycle time. At this point, the inverter reverses polarity,

and ramps the current back up again, hitting the peak at the 3/4 cycle time. The battery current is positive again,

and the inversion happens in the inverter circuit. The the current ramps down back to zero again at the end of the cycle.

The process them repeats for every cycle.

If you measure with an averaging meter, you will just see a fairly steady current that should be close to the true RMS current.

I use a True RMS Fluke meter, and it is able to give a vey accurate reading on this odd waveform.

The current reading in the BMS just measures the voltage across a shunt resistor. This reading is only taken periodically,

and it is not synced the the changing current from the inverter. It might take a reading at zero current, or at the peak current,

but most likely, it will fall somewhere in between.

Due to the shape of the wave, the reading tends to bounce a bit above and below the true RMS current.

It is not perfect, but over the long term, it is “good enough” for the BMS to calculate the amp hours charged in or discharged out of the battery.

This works because if you average the readings over a full hour, the high and low readings will average out.